Owners: H.E. Finley and Mike Higgins

Owners: H.E. Finley and Mike Higgins

Company: J&R Manufacturing, since 1974

Mike Higgins, a chemical engineer, and H. E Finley, a mechanical engineer, joined forces and families nearly forty years ago to start J&R Manufacturing. H. E. had just married Mike’s sister, and Mike had just started with the company thinking he would work in the sheet metal business. Before long he was building barbecue pits instead. It may have all started with a rotisserie smoker called the Oyler, but their line of products is much more diverse than just barbecue. They’ve grown a network of satisfied customers, and most of their growth has simply been by word of mouth. Now they are one of the most popular smoker manufacturers in the country and ship products all over the world. All of it done right in the middle of Mesquite, Texas.

Daniel Vaughn: I know you have pits all over the world. Do you advertise?

Mike Higgins: A historical problem for us has been advertising. We haven’t done much. We tried print advertising. It always seemed like money down the drain because we never had deep enough pockets to do it repetitively. We’ve also attended trade shows, but we don’t really need to do that much anymore. Our own reputation through word of mouth has been best.

DV: Do you have an idea of your market share when compared within the commercial smoker business?

MH: We really don’t. I have a feeling that Southern Pride would sell many times more than what we do. One of the reasons they use the gas and wood combination is because it’s easier to use. It still takes a long time to get it right, but you can get going pretty easily because there’s a button to push. With our cooking method you need to pay a bit more attention to the duration and maturity of the fire. We don’t want that art to be lost in this business because we feel that’s what is special about barbecue as a food type.

DV: But you also make an electric smoker, correct?

MH: We offer an electric element in our smokers as an option. It’s not designed to be the primary fuel source, but it will hold a temperature at a consistent level. It’s primarily there to cut down on wood consumption, especially for west coast customers where wood is so expensive to buy. We’re lucky here in Texas where the wood is still relatively cheap.

DV: I see a lot of your smokers as I travel around the country, but I notice more Little Red Smokehouses that Oylers. Are you selling more Oylers or Little Red Smokehouses?

MH: The Oyler is still our bread and butter. It’s a lot easier to display a Little Red Smokehouse because of their small footprint, but we know to look for the big smoke stacks to know where the Oylers are. But now you can find fake stacks. They put up these big stacks that are emblematic of the Oyler, but they’ve got something else in the smoke house.

DV: One thing I also notice is the diamond plating pattern on the exterior of the smokers. Has that always been a J&R signature?

MH: Yes. We started doing this is 1974 and the first Oylers we built then had diamond plating. We came to be known for it, so we always use it for the front plate.

DV: Have you been in this facility since you started in 1974?

MH: We’ve been here since the mid-eighties. We started off in a little dirt floor shop in Cedar Hill, Texas back in 1974. That’s where we built the first Oyler pit. We paid a royalty to the inventor’s [Herbert Oyler] widow. We didn’t know one end of a barbecue pit from the other. We were in the commercial sheet metal business here in Mesquite, and we had bought that building in Cedar Hill to expand the sheet metal business.

H. E. Finley: I bought the welding shop in Cedar Hill from a friend who had to sell it for $5000. It’s right there on the square. Within a few months is when Mike came to work with me, but he came in to work sheet metal. When this opportunity presented itself we shifted over to build pits. Forty years later, he’s made us both rich.

DV: And you used that building in Cedar Hill only to build Oyler pits?

MH: Yes. We didn’t even have the money to buy the materials when we started. We got a deposit from a guy named Sawyer on Irving Blvd. to build the first one. He had a coffee shop.

HEF: His name was Gene Sawyer. He was a Dallas policeman. That was down on Irving Blvd. just before Mockingbird [possibly a current Dickey’s BBQ location]. It’s right down from Slow Bone. That’s an awesome place [that uses and Oyler]. I get there pretty regularly.

MH: We went over and got a stack of hundred dollar bills from Mr. Sawyer, and then we could buy the materials to build the pit. We then had to figure out how to build it. We only had patent drawings, which really isn’t enough. Herbert Oyler had already sold a number of these pits before his death, so we went out and copied one. We did the best job we could to make it right.

DV: So, you had to go into someone’s barbecue business and take photos of an existing smoker so you could build it. Where was that?

MH: Yep. It was on Beltline Road in DeSoto. I don’t remember the name.

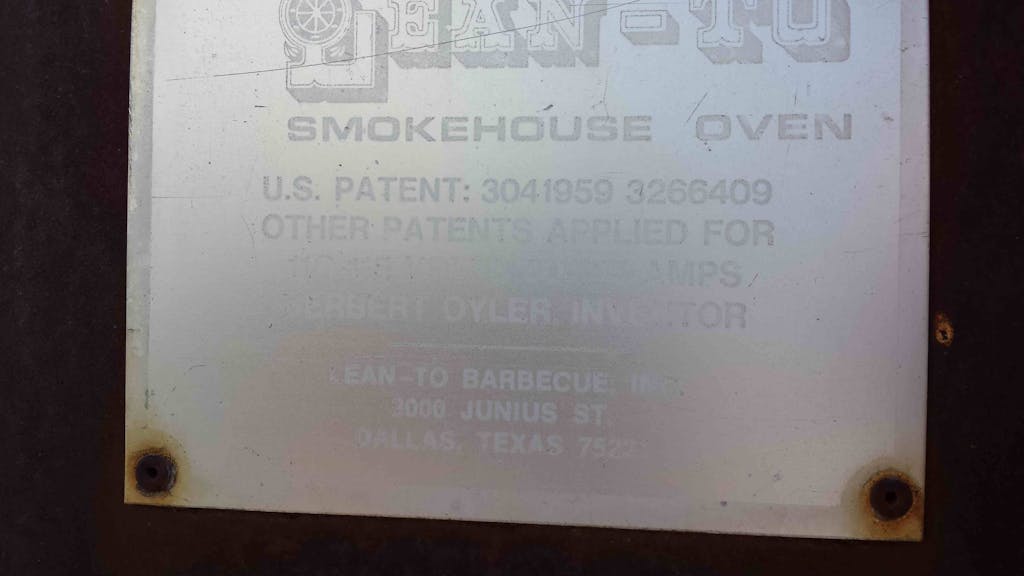

HEF: It was Lean-To Barbecue. They had one down there in DeSoto and one up on Greenville and SMU Blvd. in Dallas. The second pit we built was for a place they called “The World’s Toughest Pool Hall.” It was at the corner of Peak [actually Carroll] and Main in a two-story building that’s still there.

DV: How did you come to get the use of that patent?

HEF: The day Herbert Oyler died [January 23, 1973] I was eating with him up at his place [Mesquite BBQ in Mesquite]. He wanted to do all the work for his manufacturing right here in Mesquite. I had the sheet metal shop, and he liked me. He thought I could do the work and he could be the brains of the operation. We were just discussing. There was no deal or even a handshake. We both left. He had a shop just a few blocks away. He goes over the railroad track at grade and I go under the underpass. A train hits him and kills him.

MH: The way we hear it he had his country music up too loud in the truck and couldn’t hear the train.

HEF: It hadn’t been fifteen minutes since we’d eaten together and he was dead. His landlord Punch Rory (sp?) was in there and heard our conversation. It was six months later that Mrs. Oyler came to talk to Mike and I at our metal shop. She brought her cousin and they wanted a bunch of money to use the patent. We didn’t have a bunch of money so there was no deal. Six weeks later she came back with her lawyer. No deal. In another six weeks she comes back with Punch Rory and we negotiated a deal where we paid her $600 for every unit that went out. We ended up paying her $300,000-$400,000 over the life of the patent. It expired seventeen years after we signed the agreement.

DV: I’ve spoken with Mr. Bewley about the Oyler pit and he thought he should be the one making them.

HEF: I know Mr. Bewley. Our daughters were in school together since the first grade. When he was building those pits with Herbert Oyler, it was Herbert who did the electronics and fire box. Bewley put the skins on them. We even hired him to put the skins on the first two Oylers that we built out in Cedar Hill. I was up many times with Herbert watching him build the pits, but he was very secretive. Bewley came to Mrs. Oyler to get the patent, but Punch Rory told her that Herbert was planning to work with me.

DV: Is there any antagonism between y’all and Bewley?

HEF: No. Not from our end anyway. He’s just an old boy trying to make a living. We don’t begrudge him anything. We survived and they survived. We don’t have any animosity.

DV: So, you ran the Cedar Hill shop for a while. When did the operation move here to Mesquite?

MH: We left Cedar Hill and came to Mesquite where we worked out of many warehouses. Then we bought our first building down by LBJ. Then a few years later we built this building in the eighties.

DV: When you built this building, were you just manufacturing the Oyler, or had the rest of your line started to come together?

MH: That was 1984 or 1985. We were building the Oyler Pit and the Woodshow Broiler. We built those broilers for Dunston’s Steakhouse here in town. We added the fixed rack pits – Little Red Smokehouse and the Smokemaster – once we got into this building. Then we kept adding new products.

HEF: Even today some people think we’re just in the barbecue pit business. I hear that all the time.

DV: You built this building from the ground up. Did you run out of money for a sign? There’s just a big “820” on the roof showing the address.

MH: [Laughing] There’s a logo in the window beside the door. We never spent the money on a sign.

DV: Your last names are Higgins and Finely. Where did J&R come from?

MH: That Cedar Hill dirt-floor building I told you about, the two guys who owned it were Mr. Jones and Mr. Richey. They had an old sign that said “J&R Welding and Fabrication, Inc.” We were cheap, so we just kept the J&R part and changed the rest to Manufacturing. Then the name just stuck.

HEF: We also owned a union sheet metal shop here in Mesquite, and the new shop in Cedar Hill wasn’t a union operation. We didn’t want our names attached to it, so J&R was just fine.

DV: You now were leasing the patent. Did you know how the design of the Oyler pit came about?

MH: Mr. Oyler was a tinkerer. He developed quite a few things during his lifetime, but the Oyler pit was his claim to fame. He decided to breed a big bread making oven to a firebox. It was a remote firebox that ducted the smoke into the cooking chamber.

HEF: Supposedly he got the idea of the barbecue pits from a place out in Wikieup, Arizona. They had a place out there with two clay pots connected by a terra cotta pipe. They’d build a fire in one and the cook the meat in the other and the smoke traveled through the pipe. That’s what he based it off of.

DV: I’ve heard that Herbert Oyler didn’t ever use a rotisserie pit in his barbecue joint here in town. Is that true?

MH: He had a fixed rack pit of his own design that he used, but he didn’t use a rotisserie smoker. He was probably just too cheap to buy one. You know, plumbers have leaky pipes too. His place still survives here as Mesquite BBQ.

DV: Do they use an Oyler now?

MH: They do.

DV: Is there really any competition out there of another manufacturer that does wood-fired rotisserie pits?

MH: Not really.

Keith Stewart: One thing that really sets us apart is the UL and NSF listings.

MH: That was one of first really good decisions. We decided from the start to get listed. UL didn’t want to talk to us for the first couple years. They didn’t know what category to put us in. We kept trying to install them in other cities and they wanted to see our listing. We just couldn’t expand without the listing. Dallas Laboratories deemed it safe, but that didn’t work for every municipality. We kept asking UL and they finally said okay. They put us in the heating and air conditioning category.

DV: How many Oylers do you make every year?

MH: I’m not sure. We probably do forty or fifty Oylers and about the same amount of flat rack pits. We do two sizes of each – the 700 and the 1300. The 1300 holds about a thousand pounds of meat. Mighty Quinn’s in New York has one and they’ve ordered three more.

DV: Do they come with a recipe book?

Grant Stone: It does.

DV: Really?

GS: Yep. We can get you a copy of that if you like.

DV: I would be afraid of the barbecue joint that needs that recipe book. How long does it take to build an Oyler?

GS: We tell people it takes six to eight weeks.

DV: Your company builds them to last, and sometimes that is to your detriment. There are a lot of used Oylers out there. How much does that effect your business?

MH: We didn’t build in obsolescence. Some of them from the early seventies are still out there.

DV: Do you have people calling you asking for used ones?

KS: Yes. And I have to explain to them that it’s not my job to find them a used one. We’re in the business of selling new pits, but we’ll support anyone who has an Oyler. We’ll sell them parts and hopefully a second pit.

DV: What is the craziest place you’ve found an Oyler pit?

HEF: We did pits for Big Al’s, Sonny Bryan’s, Austin’s and Red Bryan’s here in town, but Mr. Oyler had one in the Haymarket dining room in the original Conrad Hilton hotel in Chicago. It was sitting in a pen with hay on the floor. The barbecue pit was sitting right in the middle of the room. He also pulled one up to New York to the World’s Fair in 1964 to show folks how to make barbecue. Also, our parts guy went to a joint in McAlester, Oklahoma called Jay Henry’s BBQ & Burgers. He had one from way, way back and it was labeled for Lean-To, which was one of Herbert’s first customers.

DV: How many people do you employ?

MH: About twenty-five.

DV: And how is business trending?

MH: We’ve had one of our better years. Barbecue is a good business to be in right now. New York City has just blossomed. We’ve seen that happen in other cities in the past like Boston and some on California. New York was actually a fortress for a while, but something has changed. We tried to go in for years and the Metropolitan Electrical Authority didn’t want any wood cooking in New York, so they just kept us out. Something changed about five years ago to make it easier. In the past we could do site specific testing like we did at Dinosaur BBQ and Pearson’s, but now there’s no need for that.

DV: You provided the pits for Robert Pearson’s first barbecue joint in New York?

MH: Yes. He’s a good friend. He still lives in New York.

DV: You really started selling to joints in the Dallas area. How well have you been able to sell pits all over Texas?

MH: We’re all over Texas.

DV: Are there any chains that you work with?

MH: We supply Oylers and warming pits to Rudy’s. Also, Luther’s BBQ was a big part of our early history. The Luther’s in New Orleans was the first $50,000/week barbecue joint I’d ever heard of, and that was back in the seventies. They started building franchises across the country and got us really busy. Pillsbury bought the chain then shut down the expansion. We had a two hundred unit order that we were part way through. That’s when we got the call.

HEF: We built eighty of them, but that left us a hundred twenty short on that order.

MH: That order was why this building got built. We were building about twelve Oylers a week at the beginning. It wasn’t long after we got this building finished that the plug got pulled. We had a lot of money on the table, and a lot of it was borrowed at 20% interest. We thought we were really rolling.

DV: How did you survive?

HEF: We struggled along. We had to lay some people off, but that’s the only time we’ve had to lay off anyone from our workforce.

MH: We also went to our creditors and explained to them that they would get paid, but not as quickly as they’d like.

DV: How long did it take you to get through that?

MH: It took about two to three years to get back to normal.

DV: You don’t exactly have an assembly line here. The Oylers sit in one place while someone on the floor pieces them together. I’m guessing that isn’t much different than they way you built them on that dirt floor in Cedar Hill.

MH: That’s true, but the welders are a little nicer now.