Last November, John Nielsen-Gammon, the state climatologist of Texas, traveled to Amarillo to talk to a gathering of farmers and ranchers. The day was unseasonably warm, with temperatures reaching into the mid-sixties, and typically dry. Amarillo had, at the time, received barely a quarter of its normal annual precipitation. Speaking from a raised stage in the Grand Plaza Room of Amarillo’s civic center, Nielsen-Gammon wrapped up his presentation, as he usually did, by telling the one hundred or so people in the audience that while predicting future precipitation was hard, he had little doubt that temperatures in the state were slowly rising over the long term. After he finished, a listener raised his hand.

“You don’t believe in all that Al Gore global warming nonsense, do you?” asked the man, who looked to be in his fifties.

Nielsen-Gammon, a native Californian with three degrees from MIT and a ready laugh, smiled at the question and fielded it easily. He acknowledged that parts of Al Gore’s Academy Award–winning documentary An Inconvenient Truth were exaggerated or oversimplified. That was probably the answer the man was looking for. But Nielsen-Gammon wasn’t done. He added a version of his standard line: “The earth is getting warmer, mankind has a lot to do with it, and we’re going to have to deal with the consequences.”

Delivering hard truths to Texans is one role of the state climatologist, a scantly funded and, until recently, little-noticed position that was created in 1973 after the federal government disbanded its national climatology program. One recent April afternoon, as Nielsen-Gammon sat in his fourteenth-floor corner office at Texas A&M—where he doubles as an atmospheric sciences professor—his windows offered a view of dead, drought-stricken trees against a landscape that, thanks to the spring rains, was green and flourishing. Inside, with a few clicks of a mouse, he summoned colorful squiggles and lines to illustrate everything from forecasts of next week’s weather to global wind patterns.

What the data show is worrying. The unbearable temperatures Texas suffered through last summer could become the norm. Nielsen-Gammon believes that greenhouse gas emissions will cause temperatures in the state to rise an “annoyingly large” amount—somewhere in the neighborhood of three degrees by mid-century. (Adding in hard-to-predict events like volcanic eruptions, changes in solar activity, and El Niño or La Niña could push the mercury up or down a couple of degrees.) “You probably wouldn’t care much about a degree,” Nielsen-Gammon said. But “last summer, for example, was 5.2 degrees above normal, and people seemed to notice 5 degrees.”

The earth seemed to notice too. Rainfall, notwithstanding the ongoing drought, has been increasing in Texas in recent decades, owing to such likely factors as ocean temperature patterns, air pollution, and even global warming itself. But hotter weather means more evaporation. The lakes serving the parched Permian Basin already lose more water to evaporation than to the local population’s usage—and Odessa, Big Spring, and other nearby towns that draw on those reservoirs could hypothetically run out of water, despite the wet spring. The crazier the temperatures, the drier Texas becomes.

Much of the time, Nielsen-Gammon delivers these bleak forecasts to the sort of people who filled up that auditorium in Amarillo: men and women who work the land and have borne the brunt of the drought. But if the drought continues, and if climate change continues to make Texas hotter, he will find himself speaking more often to another sort of audience: titans of industry.

Texas has long been a land of booms and busts, and another industrial boom—probably the biggest since the early eighties—is under way, spurred on by low prices for natural gas. To an unappreciated degree, water is essential to this growth. Power plants require an enormous amount of water for cooling and condensing steam before returning water to the rivers. So do plastics manufacturers and oil refineries. And the people who move to Texas to work at these plants need water too, for showering and washing clothes and—though this is a want, not a need—for keeping their lawns green. Given that the state’s growth-oriented economy is expected to drive and support a near doubling of the population by 2060, that’s a tremendous amount of water running through homes and power plants and factories. (Agricultural water use, by contrast, is currently on the decline.)

If this century is hotter—and therefore drier—than the last one, when Texas built itself into a job-creating powerhouse, the economy could theoretically grind to a halt. The horrors of running out of water, as happened to the Central Texas hamlet of Spicewood Beach this year, could spread to larger cities and even big industrial plants. Water is the Achilles’ heel of the Texas economy, the one thing that can slice through our boundless confidence that we can do everything faster, better, and bigger than anywhere else. State senator Leticia Van de Putte of San Antonio recently recounted to a Senate committee an awkward conversation she had with a Michigan lawmaker last year over lunch: “The nice legislator from Michigan said, ‘Well, I just want you to know that in ten to fifteen years, when you Texans are suckin’ dirt because you don’t have any water, the jobs are gonna come back to Michigan.’ ”

The Michigan lawmaker thought he was being funny, but Van de Putte didn’t laugh, because she knew his joke contained a grain of truth. To be sure, even in the unlikely event that manufacturers were to leave Texas, or simply not move here in the first place, they’d probably find more attractive places to go than Detroit and Flint—the Southeast, for example, where climate projections call for increased rainfall. Still, the mere thought of severe water shortages has rattled everyone from lawmakers to the head of the Texas electric grid, who has put water near the top of his list of things to worry about. No one wants to see Texas become another Rust Belt, a landscape of abandoned factories and unemployed workers. With careful planning, especially by fast-growing municipalities and private industry, Texas should be able to avoid that fate. But it won’t be easy.

As the driest major city in Texas, El Paso has been coping for decades with water problems that other parts of the state only recently began to contemplate. The city lies in the Chihuahuan Desert and receives only ten inches of rainfall each year. Thanks to the return over the past few years of the 1st Armored Division from Germany to Fort Bliss, the population has increased by tens of thousands, forcing the local power company, El Paso Electric, to expand. As if to compound the challenges, the Rio Grande briefly ran dry in May, temporarily eliminating a source that last year supplied nearly 40 percent of the city’s water.

Yet if any city is prepared for such challenges, it is El Paso, and much of the credit goes to Ed Archuleta, the longtime head of El Paso Water Utilities. When he took the job in 1989, Archuleta was faced with a paradox: though the city relied on a rapidly depleting aquifer, the Hueco Bolson, it was enamored of green lawns and abounded in garment factories where Wrangler and Levi’s blue jeans got washed and washed again. In 1991 El Paso passed an ordinance that was considered draconian at the time but now looks prophetic: it restricted outdoor watering to three days a week and paid residents to tear up their lawns and replace them with xeriscaping. It also hiked rates for heavy water users, handed out rebates for water-saving toilets and washing machines, and even gave away low-flow showerheads for free—something it did again this year. Huge industrial plants that used more than 100,000 gallons of water a day and wanted to move to El Paso had to get special permission from the water utility.

These measures—a virtual all-of-the-above broadside against water shortages—helped slash per capita daily water use by 30 percent over twenty years, from 200 gallons to 139 gallons. Remarkably, despite its growth, the city uses less water overall than it did two decades ago. No heavy, water-hogging industries have moved to town—“We don’t want the smokestacks, so to speak, [which] use a lot of water,” Archuleta said—and the garment factories have left for central Mexico or Asia in search of cheap labor. This was a “good move from our perspective,” Archuleta noted. Lighter water users like hospitals and other health care facilities have taken their place, and today, he estimated, industry uses only about 3 percent of the city’s water, compared with 7 percent two decades ago.

Existing industrial operations have been conserving too. Hector Puente, an official with El Paso Electric, said that a few years ago the company’s largest power plant dramatically cut its water use by going to a “zero liquid discharge” technology, meaning that it cycles water through the plant multiple times, squeezing every last ounce of usability out of it. As another saving measure, the plant uses water that isn’t potable to begin with—it’s cleaned-up wastewater from a treatment facility. “We have always been in the desert, so water has always been scarce,” Puente said, adding that he had been expecting a call for a long time from a reporter who wanted to know how to keep a power plant running during a dry spell.

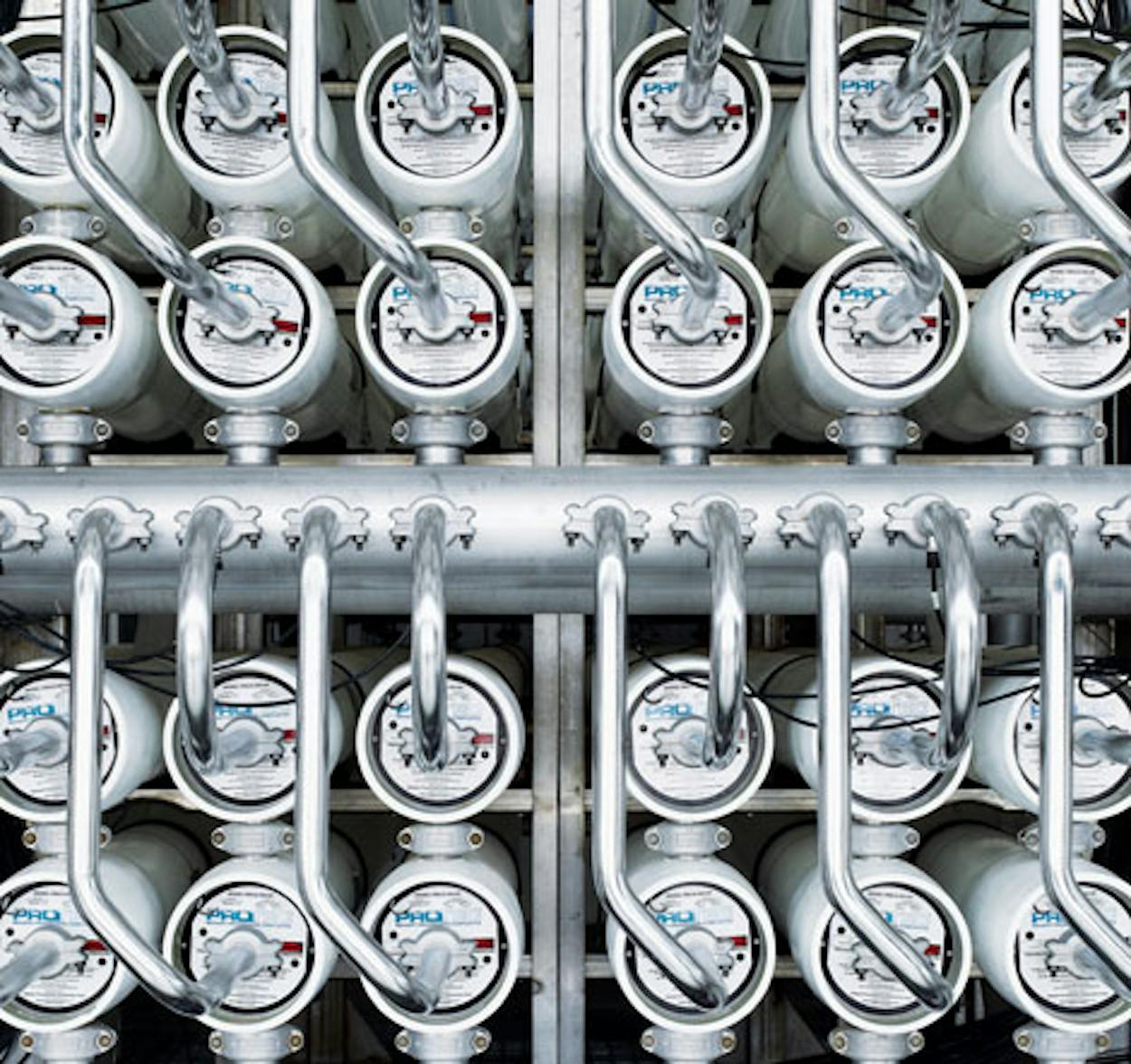

In addition to conservation, El Paso has also focused on expanding its water supplies. On a recent trip, I visited a noisy, cavernous plant on Fort Bliss land on the eastern edge of town. There, membranes resembling parchment tucked away inside huge machines filter salts and other minerals from brackish groundwater. The Kay Bailey Hutchison Desalination Plant, built in 2007 at a cost of $91 million, is the largest of its kind in the world (not including seawater desalination plants). Last year it supplied 4 percent of El Paso’s water. The salty refuse gets pumped 22 miles to the base of the Hueco Mountains and disposed of in wells as deep as four thousand feet, in an area where workers have been known to spot the occasional wandering oryx. Normally only one of the plant’s five units is running—because a huge amount of energy is needed to force the water through the membranes, desalination is very expensive—but in May, as the Rio Grande dried up, the water utility cranked up production so that all five units were working. The facility “was planned for growth, it was planned for drought, and it was planned for service interruptions,” Archuleta told me over the din inside the plant. “And we’ve had all three.”

El Paso also has one of the most extensive and advanced operations in the state for putting reclaimed water—the dinner-table term for well-scrubbed sewage—to various non-potable uses, such as watering golf courses. In addition, some of the cleaned-up effluent is pumped into an aquifer, where it gets further cleansed by nature and then comes back after chlorination as drinking water.

Other cities are coming around to El Paso’s way of thinking. In the drought-stricken Permian Basin, Big Spring is constructing a plant, possibly the first in the country, that will process effluent and send it directly back into the drinking system, without pushing it through an aquifer. And desalination is the talk of Texas. San Antonio is building a plant much like El Paso’s, Odessa is thinking about one, and everyone from lakeside residents in Central Texas to uranium miners (who dream of a string of water-intensive nuclear power plants along the coast) is advocating for the technology, which could take advantage of the ocean of saline water—equivalent to some 150 years of Texas water use—that lies beneath the state. Though it’s not widely known, much of the continental United States sits atop such resources. Texas has a lot simply because it’s so vast.

El Paso isn’t perfect: it still experiences the rich-poor divide on water issues that is common in many cities. While xeriscaping is the norm on highway medians and in middle-class neighborhoods, some of the grander houses along Rim Road overlooking the city have substantial lawns—though because of the arid climate and longtime watering restrictions, they have a fair number of brown, scruffy patches. Still, the regulations have been effective. Austin is currently mulling permanent restrictions, a step already taken by Dallas.

Archuleta seemed less than impressed. “We’ve been doing that for twenty years!” he exclaimed.

And in twenty more, the rest of the state’s major cities may finally catch up.

While municipalities slowly grapple with how to deal with a dwindling water supply, for power plants, refineries, and chemical plants throughout Texas, water planning has taken on a new urgency. In December, Lake Limestone, which supplies water to three major Central Texas coal plants, dropped to just below half full. Boat ramps built into a shoreline that had since receded by about one hundred feet led to nowhere. The upper branches of underwater trees broke through the lake’s surface. Private boat traffic all but came to a halt, and rangers with the Brazos River Authority, unable to access the lake, took to hauling their patrol boats there with tractors.

One of the coal plants dependent on the lake is the Limestone Electric Generating Station, operated by New Jersey–based NRG Energy. The plant is capable of generating about 1,700 megawatts of electricity, roughly 2 percent of the capacity of the entire Texas electric grid. During the dry winter, NRG came to a frightening realization: if it didn’t rain, the plant would be left with less than a year’s worth of water. Gary Mechler, the plant’s good-natured manager, summed up the feeling in a single word: “Scary.”

As Mechler spoke, he let out a slight laugh, signifying relief that the crisis was, for the moment, over. It was April, and he was staring at the lake through the windshield of a pickup truck. Heavy spring rains had swelled it to nearly full, but the recent troubles were still on his mind. Last Thanksgiving the nearby town of Groesbeck, which draws from a different water source, came within a few weeks of running out of water, and NRG began planning for the possibility of the same thing happening at Lake Limestone. Mechler approached the local groundwater district about drilling wells to obtain a supplementary source of water, but doing so would have provided enough for only one of the plant’s two units. The dozen or so wells would have cost millions, and NRG had to reassure the local residents that it would take care of them if their personal wells were affected.

As the heat and drought took hold last summer, NRG was also worried about some of its other operations. Its Cedar Bayou natural gas plant near Houston had plenty of water, but the weather was so dry that dust collected on the electrical insulators outside the plant, which can lead to equipment damage and even fires. The facility had to be shut down periodically on weekends to hose the equipment off. Reservoir levels at the company’s South Texas Project, a nuclear power station that draws water from the Colorado River, were also dropping, and the company began looking at a number of options, including using saltier water—which was seeping upriver from Matagorda Bay—to cool the plant on a temporary basis. (It never had to.) “Hand-to-hand combat” is how John Ragan, who heads up NRG’s Texas operations, described dealing with the problems last year, which were compounded by the fact that the power plants were working overtime to serve air conditioners that were cranking in the record heat.

These sorts of concerns now enter the calculus of opening a plant in Texas. “When you look at a billion-dollar investment and you look at the risks associated with it, all of a sudden water has jumped up there,” said Ragan. But the risks, he insisted, are manageable, through tapping brackish water, just as El Paso and San Antonio have begun to do. “We will be filing new permits probably over the next year in Texas for new [power] generation, and they will be in places where there are abundant water resources—i.e., brackish resources,” Ragan said. (The water NRG hopes to run through its new plants will not need to go through the desalination process that’s required for drinking water.)

NRG is hardly alone in reorienting its thinking about water. Last year, many industrial plants struggled as surface water supplies dwindled, only to be bailed out by the spring rains. In September Earl Shipp arrived from Michigan to take over as vice president of Dow Chemical’s Texas operations. At Dow’s Freeport facility, a petrochemical manufacturing site that is the company’s largest industrial complex in the country, he learned that levels at the complex’s two reservoirs, which are off the Brazos River, had dropped to about 50 percent. Like the South Texas Project, the facility was also dealing with saltwater issues. “We had a saltwater plume—it was over forty miles up the river, and it was threatening to shut off the intake to our upper river reservoir,” Shipp recalled.

In response, he began scrutinizing the plant’s water use, down to the tiniest details. “Normally if you have a small steam leak, you don’t think about it,” Shipp said. But this time, Dow was going to think about it. Between October and December, it fixed leaks and started using treated water from a nearby wastewater plant for relatively small jobs, like cleaning railcars and tank trucks. By the end of the year, the plant’s water use had dropped 10 percent. “We did a little bit of everything to get that 10 percent,” Shipp said.

Drought isn’t the only motivation for cutting water use. Dow also wants to grow. Recently, driven by low natural gas prices that make it cheaper to manufacture chemicals, the company announced plans for a more than $4 billion expansion at Freeport. The four new plants will be designed with air-cooling technology and other water-saving features, so they will use half as much water as the existing facility. “A 50 percent reduction—that’s huge,” Shipp said. “Remember [how] the old VW used to be air-cooled—didn’t have radiators? You can design a chemical plant that way.”

On a smaller scale, Shipp plans to continue fixing leaks and replacing the old-fashioned water-wasting air-conditioning units on hundreds of buildings. Dow’s general philosophy, he said, is that “water is a precious commodity, and we’re going to use less of it.” Even so, last year the company bought land to build a third reservoir to serve the Freeport complex.

Seventy miles down the coast at Point Comfort, a major plastics plant was also struggling with water last year. The plant, an American arm of the Taiwanese company Formosa Plastics, produces resins that are used for molding and traffic cones. Nearly three decades ago it opened a manufacturing facility on the Gulf, and last year the company was notified by the Lavaca-Navidad River Authority that its water allocations could get cut by 10 percent if Lake Texana fell to 50 percent full. When the lake hit that level, the company began looking for new resources and implementing conservation measures, like fixing leaks and recalibrating flow meters. The plant bought 250 acre-feet of water a month from Corpus Christi and also trucked in drinking water for workers in five-gallon plastic jugs, to ease the burden on the city of Point Comfort, its water supplier. “We cut back any absolutely non-necessary use of potable water here,” said plant spokesman Bill Harvey. Just after Christmas the situation worsened: lake levels fell to 40 percent, which triggered cutbacks of 20 percent. The plant arranged to buy more water from Corpus Christi, but lake levels soon rebounded when rainfall returned in earnest earlier this year.

Bullish on the future, Formosa announced in February a $1.7 billion expansion of the Point Comfort factory. The company has rights to enough water from the Lavaca- Navidad River Authority to cover the expansion, Harvey said, though he acknowledged that “if we have another long period of drought or something like that, it’s certainly going to be problematic for us.” In the meantime, the company is working to keep the conservation going: “We’re just really being careful about how we use every drop,” Harvey said.

Though the drought has spurred Texas companies and municipalities to innovate, industries say that state lawmakers need to do their part too, by helping local governments get access to water funds, encouraging conservation, and making it easier to create reservoirs. But spending money is anathema in Austin these days, and the conversation about the drought has been warped by the political overtones of climate change. Amarillo ranchers aren’t the only ones who think that Al Gore spouts nonsense; Rick Perry, for one, has asserted that much climate change data has been “manipulated.”

“One of the things I think that saddens me the most is the politicization of this science,” said Katharine Hayhoe, a Canadian-born climate scientist at Texas Tech University. Like John Nielsen-Gammon, she specializes in translating scientific abstractions into language ordinary Texans can understand, even talking to religious groups about climate change as an extension of her own Christian faith. Sometimes when she speaks at a church, she gets questions like “If the world’s going to end anyway, why should we care?”

People who believe that the millennium is upon us are probably beyond persuasion, but facts and data, Hayhoe said, often bring people around to her arguments. Her husband, Andrew Farley, is an evangelical pastor. When they married, he was a climate skeptic, but over the years she has managed to change his mind. Three years ago they co-wrote a book, A Climate for Change: Global Warming Facts for Faith-Based Decisions, which was put out by the religious publisher FaithWords.

For her trouble, Hayhoe has been vilified. Last year she was derided as a “climate babe” by Rush Limbaugh, and soon after Newt Gingrich, in the heat of his futile presidential bid, publicly revoked his request that she write a chapter of his planned book on the environment. When I asked Hayhoe about this episode in a Texas Tech cafe, her ever-present smile briefly became a rueful grimace. The hate mail “goes in waves,” she said. “And there have been waves before that—that was not the first wave.” But she has learned to turn the other cheek, and last year she helped land the new, federally funded Climate Science Center at Texas Tech, which will study weather patterns in the south-central United States and help the public understand the implications of climate change.

Hayhoe has no illusions that large numbers of Texans will suddenly come around to recognizing man’s role in creating climate change. But to some degree, she believes that the issue of what is causing our hotter and sometimes drier weather is irrelevant. Texas is getting warmer, and we need to deal with it. Which shouldn’t be impossible, given that Texans have been dealing with extreme weather since the state’s founding.

“The reason why we care about climate change is not that it’s inventing these new issues, in most cases,” Hayhoe said. It simply exacerbates problems that we already have, such as West Texas’s vulnerability to drought, our depleting aquifers, and the air pollution that plagues many cities (think of all those summer ozone alerts). Over the decades, Texas, with help from the federal government, which has funded megaprojects like dams, has dealt with many of these challenges and turned itself into the nation’s economic juggernaut. But that success has bred its own challenges, in the form of a booming population and a booming economy that put tremendous demands on our water supplies. If the next one hundred years are going to be as successful as the past one hundred, Texas will have to figure out how to deal with a state that’s getting bigger, hotter, and drier all at once.