The coronavirus pandemic has transformed the country in just a handful of weeks. As Americans focus on the essentials—feeding our families and ensuring we have the necessary supplies to keep our households clean and safe—grocery stores and pharmacies have demonstrated just how crucial they are to a functioning society.

We’ve seen chains struggle with the challenges the current crisis presents. Some stores are instituting policies limiting the numbers of shoppers allowed in at a time, creating long waits to enter. Perhaps even worse, other stores are not, leaving their shops a free-for-all without adequate social distancing measures. Staples like flour and yeast, to say nothing of hand sanitizer and toilet paper, are proving difficult to find on shelves. Supply chains are taxed. And the conditions faced by employees vary wildly by chain, with stores developing new (sometimes controversial) policies around sick leave for the workers who have proved themselves essential, and often doing so on the fly.

San Antonio-based H-E-B has been a steady presence amid the crisis. The company began limiting the amounts of certain products customers were able to purchase in early March; extended its sick leave policy and implemented social distancing measures quickly; limited its hours to keep up with the needs of its stockers; added a coronavirus hotline for employees in need of assistance or information; and gave employees a $2 an hour raise on March 16, as those workers, many of whom are interacting with the public daily during this pandemic, began agitating for hazard pay.

This isn’t the first time H-E-B has done a good job of managing a disaster—it played an important role in helping the Gulf Coast recover from Hurricane Harvey in the immediate aftermath of the storm—which led us to ask: How did a regional supermarket chain develop systems that allow it to stay ahead of a crisis as big as this one? We spoke with nearly a dozen employees, executives, and customers to better understand—in their words—how H-E-B has taken on its unique role in shaping its business around the needs of Texans in the midst of trying circumstances.

Before the Outbreak

Justen Noakes, director of emergency preparedness, H-E-B: Just a little bit of history: we have been working on our pandemic and influenza plan for quite a while now, since 2005, when we had the threat of H5N1 overseas in China. That’s when we first developed what our plan looked like, [as well as] some of our requirements and business implications. In 2009, we actually used that plan in response to H1N1, when the swine flu came to fruition in Cibolo, and refined it, made it more of an influenza plan. We’ve continued to revise it, and it’s been a part of our preparedness plan at H-E-B ever since.

Craig Boyan, president, H-E-B: Justen leads our emergency preparedness with a group of folks, and that is a full-time, year-round position. We are constantly in a year-round state of preparedness for different emergencies. We keep emergency supplies at almost every warehouse and have water and other supplies staged and ready to go and kept in storage to make sure that we are ready to [react quickly] when a crisis emerges, whether it be a hurricane or a pandemic. We take being a strong emergency responder in Texas, to take care of Texas communities, very seriously.

On January 15, Wuhan’s Municipal Health Commission announced that the novel coronavirus was spreading via human-to-human transmission.

Justen Noakes: So when did we start looking at the coronavirus? Probably the second week in January, when it started popping up in China as an issue. We’ve got interests in the global sourcing world, and we started getting reports on how it was impacting things in China, so we started watching it closely at that point. We decided to take a harder look at how to implement the plan we developed in 2009 into a tabletop exercise. On February 2, we dusted it off and compared the plan we had versus what we were seeing in China, and started working on step one pretty heavily.

Craig Boyan: Starting in January, we’ve been in close contact with several retailers and suppliers around the world. As this has started to emerge, we’ve been in close contact with retailers in China, starting with what happened in Wuhan in the early couple of months, and what kind of lessons they learned. Over the last couple of months, [we’ve been] in close contact with some of our Italian retailers and suppliers, understanding how things have evolved in Italy and now in Spain, talking to those countries that are ahead of us in the curve. We’ve been in daily contact, understanding the pace and the change and the need for product, and how things have progressed in each of those countries.

Justen Noakes: We modeled what had been taking place in China from a transmission perspective, as well as impact. As the number of illnesses and the number of deaths were increasing, obviously the Chinese government was taking some steps to protect their citizens, so we basically mirrored what that might look like. We also took an approach to what we saw during H1N1 in 2009, and later got on top of it. Our example was if we were to get an outbreak, specifically in the Houston area, how would we manage that, and how would we respond with our current resources, as well as what resource opportunities would we have.

Craig Boyan: Chinese retailers have sent some pretty thorough information about what happened in the early days of the outbreak: how did that affect grocery and retail, how did that affect employees and how people were addressing sanitization and social distancing, how quarantine has affected the supply chain, how shopping behavior changed as the virus progressed, how did companies work to serve communities with total lockdowns, and what action steps those businesses wish they had done early in the cycle to get ahead of it.

Preparing Employees

Justen Noakes: One of the biggest things we’ve looked at is what are the impacts to their employees? How they dealing with the health of their employees? We’re very interested in what’s happening in the supply chain world, and the products that are being affected. How are they running their stores when they’re impacted by absenteeism? We’re trying to get answers so we can get ahead of this and really understand how the overall operations of their companies are being impacted.

On February 12, the first coronavirus case was found in Texas. Over the next month, certain products started becoming scarce, and on March 14, H-E-B announced it would be reducing store hours to 8 a.m.–8 p.m.

Justen Noakes: Going to eight-to-eight has been in our playbook all along, but I think what drove it for us was trying to ensure that we had enough product on our shelves to take care of our customers. That’s really what we needed—we needed a little bit of extra time to stock all the groceries that were coming in.

Tina James, chief people officer, H-E-B: [Our partners] have responded exceptionally well. Our volume is up tremendously in our stores, and [as far as] our culture, we are incredibly dedicated and engaged. I have been amazed and humbled by how positive their spirit is, and how great they feel to be serving our customers. That said, it’s fairly exhausting work, and the volume has been so substantial that we’ve cut our hours back.

Michael Leas, stock controller, store number 351, Edna: My overnight crew, they’re just coming in, and it seems like they’re ready. They just ask me what I need them to do. I haven’t had very many complaints from the guys or anything. It’s been really nice. You can tell that they understand it’s not our fault; this is just something that’s happening.

Craig Boyan: We’re not in a super glamorous job. We have a lot of hard-working people doing hard jobs. But there’s a strong sense of pride at H-E-B. We describe ourselves as a purpose-driven company, and we’re at our best amid times of crisis. There’s a great sense among H-E-B partners that they’re doing what’s needed to take care of Texans, and that keeps the morale very high.

Tina James: For example, when we saw what was happening with the volume, we asked at corporate if people wanted to volunteer to take shifts in the stores and at the warehouses. We immediately had hundreds—800 corporate folks volunteered for 350, 400 shifts in our stores and warehouses, to be able to help out and give some relief to our stores.

Stephanie Lowe, customer: I met Alma, who has been with H-E-B for 21 years, if I recall, and works in the store’s bookkeeping department. She had answered the “all hands on deck” call and was working checkout for the first time in years and she was so excited. She kept saying how much fun she was having being back at checkout and took great delight in looking up the codes to ring up produce. It was such a positive interaction in the midst of organized chaos, and I have thought about it throughout the week at work when things have been stressful.

Making work fun while we go thru this crisis 😂🤩 #HEB #HEB18 pic.twitter.com/48ni3trMm1

— lesliee✨ (@Lesliemarieq) March 19, 2020

https://platform.twitter.com/widgets.js

Command Central

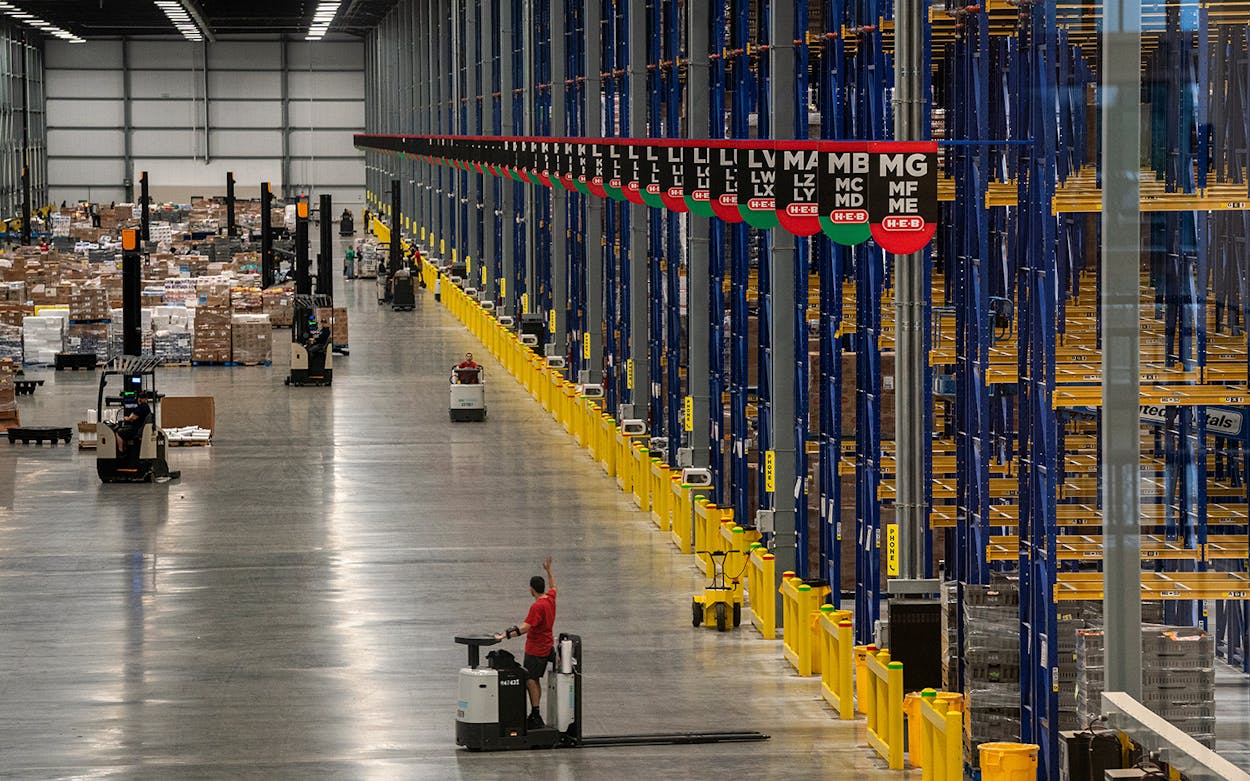

Justen Noakes: We activated our Emergency Operations Center in San Antonio on March 4 [the EOC is run out of H-E-B’s new 1.6 million-square-foot super-regional warehouse]. The driving factor behind that is when we see even a potential upswing in customer activity due to one of these events. The Emergency Operations Center at H-E-B is a collection of the most impacted areas of the company, and the leaders in those areas are brought together to make streamlined decisions and collaborate together on a daily basis. That’s almost every area of the company, so we’ve got a lot going on in our emergency operations center right now. It’s very busy.

Dya Campos, director of government and public affairs, H-E-B: Even in the EOC right now, we’re practicing social distancing here. We’re all very far away from each other, and we’re very careful around each other, and taking precautions to take care of each other.

Tina James: There’s so much product coming through the super-regional headquarters where the EOC is that we’re having two hot meals delivered every day, for the partners who work here. We also have set up an essential store for them within the warehouse, because it’s difficult for them to get to a store during the new hours, so they’re able to pick up canned items, toilet paper, peanut butter, and water.

Trying to Keep Up

Craig Boyan: When a hurricane happens, it’s in an isolated part of the country. We’re quite good at pulling product from around the rest of the country and feeding it to Texas. That is much more difficult in a pandemic, where every area of the country is under real stress. So our suppliers, where we’re getting paper towels from, our wipes, our hand sanitizer, are getting hit from all retailers, and we are seeing much higher levels of out-of-stock [goods] as a result. We’re working really hard to be creative in how we source product when the supply chain is under real pressure.

In early March, retailers around the country started seeing shortages of common household products, and H-E-B began limiting quantities that customers could purchase on a single trip.

Justen Noakes: What we really started seeing first was runs on N95 masks. I think people were sending the masks back home to their families, and it started exponentially increasing at that point, particularly around cleaning supplies, disinfectant, things of that nature. But I don’t think anybody saw the toilet paper rush coming.

Craig Boyan: We did not see runs on toilet paper as one of the first things to go out of stock. That was something we still kind of have a hard time understanding.

Michael Leas: When we get to work, it’s been empty in the stores, certain sections, like the paper aisle, water, just a bunch of stuff. Bread is just completely blown out, so it’s been kind of weird. They changed our hours too. So we’re coming in a couple of hours earlier and staying a little bit later now, at night … My store is a tiny little store. It’s got nine aisles. So it’s like a big Walgreens.

Craig Boyan: We have a number of Texas companies that are pitching in and doing great work. I can give you a few examples: Labatt is a food distributor here in Texas. Their primary customers are schools, institutions, and restaurants. Obviously those businesses are under real pressure, and many of them are shutting down. So we have been partnering with Labatt to deliver rotisserie chickens, deli lunch meats, and a variety of products.

Blair Labatt, president, Labatt Food Service: We just sort of bolted onto H-E-B’s need in the conventional grocery supply with our trucks and drivers, because obviously our core restaurant business is very adversely affected by the crisis, so it’s really worked out well for us.

Craig Boyan: We’re partnering with the beer distributors in Texas, for the first time ever, to deliver eggs to our stores. We’re seeing these types of businesses coming together in a powerful way to support each other, and it’s a wonderful thing.

Michael Leas: There have been some nights where the paper [aisle] is out and just didn’t really get restocked. But then there’s nights where it gets completely jam-packed with products. It almost feels like we’re coming into an empty store, and we’re completely filling it up every night. You will have a little bit of of holes here and there throughout the store, but it’s just not that bad.

Craig Boyan: We’ve been working very hard right now to deliver meat and poultry and eggs to our stores. We’re accelerating opening a new warehouse in Houston that was due a few months later. We’re taking some of our warehouses in the state and transitioning them over to serving just meat, because we’re seeing such significant demand for meat, poultry, and eggs. We’re still having a real hard time sourcing eggs. We had big loads in the last few days, and they’ve been scooped up as soon as they hit the shelves, so we’re working very hard with egg suppliers to see where we can get additional eggs. But our meat plant is running 24/7—we have our own meat plants here. They normally don’t go 24/7, but we’ve focused them down to serving the top fifty items out of our meat plants; they normally carry several hundreds. [Focusing on top items] means fewer changeover delays, and it allows us to ship significantly more meat. We’re seeing those kinds of moves across the board as we look to ramp up volume in a rapid way.

Zak Houram, customer: Nothing was super out of stock when I was there last. The staff is super friendly and upbeat, with all things considered. One store [a Central Market] is in Southlake and the other is in Fort Worth, off of Hulen. The Hulen store was considerably better stocked, but Southlake is still better compared to the Targets and Krogers and Tom Thumbs I’ve been to.

The Great Unknowns

Justen Noakes: We’re here to take care of our partners, take care of our customers, take care of our community. So I think that that’s really our number one focus, and what we’re really trying to do is to meet those objectives—but I will tell you that the challenge of it is the longevity. With a hurricane, you can see the wind coming, you can see the rain. You can see an end in sight. We’ve been having conversations about how this equates to Harvey, and although the need is very similar … there is not really a clear end in sight on when we think we will be out of this. On a twice-daily basis, we’re monitoring trends in Europe and China, so we can forecast an estimate on when we think we’ll be out of this. But unlike a hurricane, we just can’t see it.

Tina James: When we have a hurricane, we often know fairly quickly which of our partners have been impacted. At this point, we can only project from a personal impact statement, so at this point, we don’t know.

On March 11, President Trump gave a prime-time address about the response to the virus. That same evening, the NBA announced that it would be suspending its season, and actors Tom Hanks and Rita Wilson announced they had both contracted COVID-19.

Craig Boyan: We’ve had several different spikes, but one of the most significant was [around March 11], when we saw a second furious wave of buying. I don’t know if it was the announcement that the NBA had shut, or one of the presidential news conferences, or Tom Hanks, but we saw a major spike that day. And we’ve seen increased spikes since.

Michael Leas: The cleaning aisle has been insane lately. The canned aisle has been insane. Sugar is one thing that’s been out of stock a lot lately, but it feels like they started concentrating on that too. There’s certain things, water, definitely water. We’re getting trucks with just water, which is not normal.

On March 16, local officials ordered bars and restaurant dining rooms in Houston and Dallas to close; Austin officials made the same decision the following day.

Justen Noakes: I would say rural and urban stores are very consistent, as far as the increase. What we are seeing is a little difference as far as the timing goes. I think that’s directly related to confirmation of cases. You’re also seeing local governments come in and issue quarantines like closing restaurants and bars, and I think that really fuels some of the purchasing and shopping, and as that goes from town to town, and as cases increase in other towns, that’s what’s driving it for a lot of our shoppers.

Michael Leas: We’ve had a lot of extra help from people that aren’t stockers, a lot of day crew, the cart pushers or the baggers. They’ve been coming in early in the morning to help us stock the shelves. These trucks have been massive. Our heaviest aisle during the holidays is a canned aisle, and you’ll get maybe about three cases. That’s a pretty heavy night for our little store. Last night we had over seven hundred cases on that [aisle]. Some of these aisles have been two, three times heavier than they normally are.

Let’s talk about how NO STORE DOES MORE THAN @HEB. pic.twitter.com/8KmKcD3422

— Jess Elizarraras (@JessElizarraras) March 23, 2020

Jessica Elizarraras, customer and bride: Our wedding was supposed to take place on April 5, [but] it didn’t make sense for us to try and have this party. So we scheduled everyone—the officiant, co-maids of honor—for Sunday at 4 p.m. and scrambled for a photographer. But I didn’t think of flowers. By Saturday, we didn’t feel comfortable running around San Antonio finding flowers. So I emailed the H-E-B Blooms department at 5:59 p.m. and received an answer almost immediately. [H-E-B corporate designer] Andy Hopper called us on Sunday morning, went to the wholesaler, found a few goodies and whipped up this amazing bouquet. We picked it up at the Lincoln Heights H-E-B, and he even included a boutonniere for TJ, which I didn’t even think to order (bridezilla, much?)! Given the circumstances, I didn’t think they could spare anyone. They truly made our day. A bride needs a bouquet and I ended up with a gorgeous one because they cared enough to make it happen, COVID-19 or not.

Lessons Learned

Craig Boyan: Any experience, you learn from and you continue to get better. The way we focus on pushing our business is to try to adapt as quickly as humanly possible, as we talk about the daily adjusting of our supply chain and our store operations.

https://www.instagram.com/p/B97vSXAJgk8/

Justen Noakes: The most important lesson for us is to listen to what’s going on in our stores. When we started seeing the N95 masks and the sanitizers, we took that as a good sign that our customers were concerned about what was going on, and that’s what really spurred us to activate our program. That’s the biggest one—to make sure that we’re really paying attention to what our customer does, and to actually respond to it. As we continue to maneuver our supply chain and support our stores during COVID-19, we’ll bring some lessons learned and tools out of that into hurricane season.

Dya Campos: One thing we learned from Hurricane Harvey is that our customers want to hear from us. They want to hear our perspective, they want to know what we’re doing, what we’re thinking, how we’re helping our communities.

Bernice Calderon, customer: Whoever is managing their crisis communication is on top of it. And all of their staff has been just as friendly as ever. I did a quick grocery trip on Saturday, and my favorite H-E-B employee told me she missed me cause she hadn’t seen me and “Que dios la bendiga.” I mean!

Tina James: It’s not lost on us that we are offering an essential public function, and it’s not lost on our partners, either. And they continue to come to work with a very positive attitude, and continue to serve above and beyond even their normal hours. That never ceases to amaze me. We are very fortunate in that H-E-B has a chief medical officer as well as a medical board, so we have resources at our fingertips to offer up medical advice and guidance to our partners. So we play a unique role in our partners’ lives that allows them to have some comfort and calm so they can turn around and take care of our customers.

Blair Labatt: It’s inspiring to see people rally around and meet a crisis. It’s uplifting to see people cooperate, and energizing to see that all happen. The whole process has been one huge unified response.

Y’all remember when Titanic was sinking and the band was still playing?

— TEXAS FOREVER (@_TexasForever) March 14, 2020

Here’s H-E-B version of it while people are freaking out over the corona virus

Schertz, TX pic.twitter.com/b0DOYoqlw0

Dya Campos: A customer sent mariachis in appreciation! We feel a lot of that.

Craig Boyan: The spirit of Texans and their treating H-E-B partners with the respect and pride that they do makes us feel fantastic. I drove by a church the other day in San Antonio that had a sign out front that said ‘Thank an H-E-B checker.” We’ve seen an outpouring of support for our partners and truck drivers that gives us a great sense of pride.

As we cover the novel coronavirus in Texas, we’d like to hear from you. Share with us your tips or stories about how the outbreak is affecting you. Email us at [email-hidden].