Rajani Srinivasan remembers a host of aromas drifting out of her childhood kitchen in the northern Indian state of Uttar Pradesh. Her family had relocated there from the south of the country, so Srinivasan’s upbringing left her with a love for bhindi masala, a popular okra dish in the north, as well as sambar, a stew made with bittersweet fenugreek and tangy tamarind that’s popular in the south.

These foods came to mean much more to her, in surprising new ways, once she set out on her studies as a young graduate student in applied chemistry in Kanpur, a city on the banks of the Ganges River. Her adviser was studying how polymers—materials made of long chains of molecules—could be used to advance wastewater treatment. Srinivasan began tinkering in her lab with common synthetic molecules, but also unorthodox natural polymers—including some derived from vegetables, fruits, and spices.

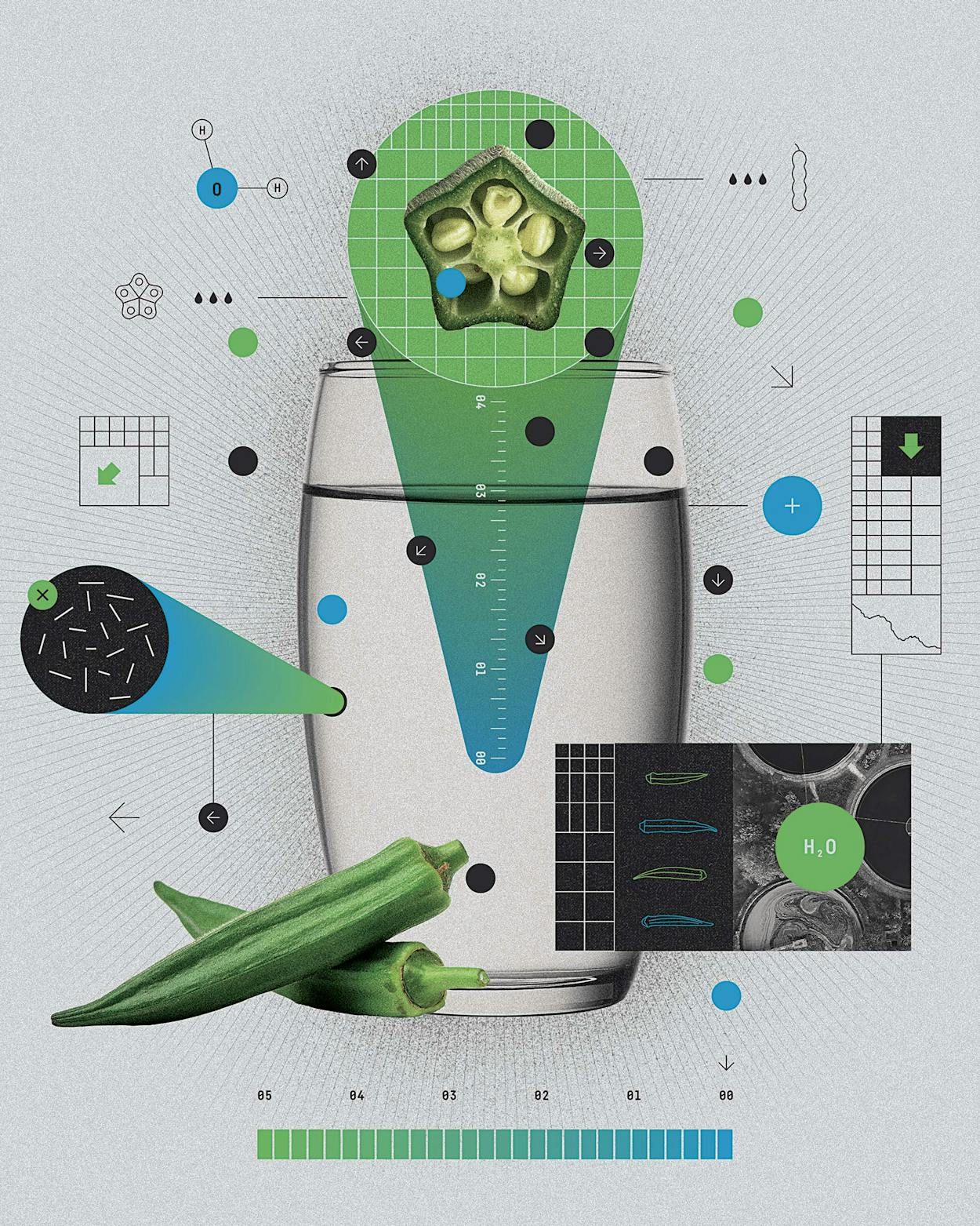

Decades later, she’s still at it—with her research focused on components she knows well from her childhood: okra, fenugreek, and tamarind. Now an associate professor of chemistry at Tarleton State University, in Stephenville, about seventy miles southwest of Fort Worth, she, along with her team of researchers, recently discovered that these ingredients can remove microplastics from water, reducing the likelihood that those pollutants will be consumed or harm sensitive ecosystems.

Microplastics, which are tiny plastic fragments no bigger than five millimeters, may splinter off larger objects—such as shopping bags, water bottles, or PVC pipes—and get swept into culverts, washed into streams, or flushed down bathroom sinks. They can also seep out of products such as toiletries and cosmetics, and they end up seemingly ubiquitous on land and in bodies of water across the globe, accumulating in alarming densities and causing health problems for all manner of aquatic animals. Researchers have estimated that as many as 463,000 tons of microplastics settle on the seafloor each year.

The threats to human health posed by microplastics are not fully understood. A recent peer-reviewed study showed that human lung cells that were exposed to microplastics proliferated at a slower rate and underwent structural changes. Some scientists fear microplastics exposure could result in respiratory damage, metabolic disturbances, or increased risk of cancer, but more research is needed to achieve any kind of consensus. Yet even if they aren’t harmful on their own, microplastics can be vessels for toxins. Two studies published in the journal Environmental Science & Technology have estimated that each of us unintentionally consumes or inhales at least tens of thousands of microplastic particles—adding up to roughly the mass of a credit card—every year. Many of those particles pass through the body and get excreted as waste, but scientists have also found microplastics in the lungs, blood, and placentas of human research subjects.

One common solution for getting microplastics out of water, though, has its own drawbacks. Many drinking water and wastewater treatment facilities use synthetic chemical additives as what are called flocculants, which attract microplastics and other suspended solids, causing them to clump together and sink to the bottom, where they can be removed. Yet the chemicals commonly used as flocculants may themselves be toxic.

According to the World Health Organization’s 2017 Guidelines for Drinking-water Quality, a component of one common flocculant, polyacrylamide, can cause cancer. This material is used in extremely low doses in water treatment, but some worry about the trace amounts that linger in water supplies. “If we are removing microplastics and in turn adding some materials which are toxic to us,” Srinivasan said, “it does not make a lot of sense.”

Srinivasan left India in 2005 to join her environmental-scientist husband, Narayanan Kannan, in Temple, where both worked at the Blackland Research & Extension Center, part of the Texas A&M Agrilife program. In her six years as an assistant research scientist at Blackland, Srinivasan continued to experiment with improving water quality. In 2012 she took the job at Tarleton State so that she could return to teaching chemistry while continuing her research.

It wasn’t until 2019, after learning about the threats posed by microplastics, that Srinivasan began testing extracts of okra, fenugreek, and tamarind to see if they might be part of the remedy. She was familiar enough with the chemical structures of each to know that theoretically they should work. Eventually, in 2020, she and her team found a combination that worked as well as, or even better than, flocculants currently in use—and without any risk of toxic residue.

During a presentation in March at the American Chemical Society’s spring meeting, Srinivasan made her case for plant-based treatments for microplastics contamination. She explained that she and her students used polysaccharides (a type of carbohydrate) drawn from several natural products and created flocculants that allowed them to isolate and remove microplastics from water sources. Combinations drawn from okra and tamarind, in equal parts, worked best for fresh water. For ocean water, it was extracts of okra and fenugreek.

If Srinivasan’s food-based approach to microplastics removal works on a large scale, as she hopes, it won’t be the first time she’s helped clean up Texas water. In 2016 Srinivasan began partnering with the High Plains Water District, based in Lubbock, to test methods of removing contaminants from groundwater pumped from the region’s aquifers. The Dockum Aquifer there naturally contains arsenic, an element associated with cancer. Because of the poor water quality, portions of the aquifer can’t be used.

“I think it seems like a really good idea,” says Susan Bratton, a professor of environmental studies at Baylor University whose research has documented the presence of microplastics in ecosystems throughout Texas. Bratton and one of her students recently published a study that took samples from the Brazos and San Marcos rivers, among other nearby watersheds. At the study’s outset, the researchers hypothesized that samples taken from areas in dense urban centers, or downstream from wastewater discharge points, would contain significantly higher levels of microplastics, but the results were surprising. Even relatively remote stretches of crystal-clear streams, such as the San Marcos River, contained microplastics. “That’s coming out of a huge limestone high-volume spring,” Bratton says. “That’s some of the clearest water in the state.”

Srinivasan has also partnered with the High Plains Water District, based in Lubbock, to test methods of removing other contaminants from groundwater pumped from the Ogalalla and Dockum aquifers. The Dockum aquifer contains arsenic, a mineral associated with cancer. Jason Coleman, general manager of HPWD, says Srinivasan has used plant-based polymers—similar to those created from okra and tamarind—to target dissolved solids like arsenic in groundwater pumped from the High Plains with the intention of binding it so it can be separated from the water. “The deepest of our three aquifers happens to be one that contains more areas of higher total dissolved solids,” Coleman says. “[Srinivasan’s] research on that front has been particularly meaningful for people in our area.”

The plant-based combinations that Srinivasan’s team have developed are ready-made for water treatment plants. Srinivasan says her compounds are interchangeable with chemical flocculants already in use at many facilities. “You do not have to have any new infrastructure built,” she says. “Just replace the synthetic materials that are being used with these materials.”

Srinivasan’s work on the Dockum Aquifer used plant-based polymers—similar to those created from okra and tamarind—to target and separate out dissolved solids from the groundwater. “The deepest of our three aquifers happens to be one that contains more areas of higher total dissolved solids,” said Jason Coleman, general manager of HPWD. “[Srinivasan’s] research on that front has been particularly meaningful for people in our area.”

Some experts think Srinivasan’s approach could have other, unexpected benefits. Audra N. Morse, a professor of environmental engineering at Michigan Tech University, noted that the use of synthetic flocculants can result in a potentially toxic by-product, whereas the by-product of using natural flocculants might be reused as compost or a soil additive. “I think that move toward more green chemicals is always a positive,” she said.

The plant-based combinations that Srinivasan’s team has developed are intended to be ready-made for water treatment plants. “You do not have to have any new infrastructure built,” Srinivasan said. “Just replace the synthetic materials that are being used with these materials.”

Neither the state nor the federal government specifically requires water treatment facilities to target microplastics in water supplies. (Some Texas industrial wastewater facilities, however, are prohibited from discharging plastics.) A 2019 WHO report noted that traditional wastewater treatments can eliminate 90 percent of microplastics already, and Bratton, the environmental scientist from Baylor, said her researchers did not detect a significantly higher presence of microplastics near wastewater treatment sites.

But some states have begun studying microplastics as potential contaminants, and California is the first to begin monitoring microplastics levels in its water. So it’s only a matter of time before products such as her okra-tamarind concoction are in widespread use, Srinivasan believes. Indeed, in both Dallas and Fort Worth, city staff have begun to consider ways to reduce the presence of microplastics in water supplies.

Still, some experts wonder if Srinivasan’s method will prove feasible once it’s scaled up to serve major municipal water operations. “The idea of wanting to replace synthetic organics with natural organics is a good one,” said Desmond Lawler, a professor emeritus of environmental engineering at the University of Texas at Austin. But Lawler notes that the amount of polysaccharides that Srinivasan calls for when targeting microplastics is far greater than what’s required when using synthetic flocculants. Unless Srinivasan’s polysaccharide mixture “could be used at a far, far lower concentration than what she’s talking about,” Lawler said, “I don’t know that it really has short-term value in the industry.”

Others agree that Srinivasan will likely need to make adjustments but are more optimistic that potential obstacles can be overcome. “I do think those questions are going to have to be answered,” said Andrew Jackson, a professor of environmental engineering at Texas Tech. “But I’ve seen a lot of technologies that on the face of it, you would think, well, it’s never going to work, and people do make it work.”

Srinivasan’s research has yet to be published in a peer-reviewed journal, and any potential plant-based flocculant would need to clear permitting hurdles, not to mention be marketed to water treatment specialists. But Srinivasan is confident enough in her findings that she’s already seeking ways to scale up. She has begun working with one renewable energy company and hopes to partner with others that can handle large-scale production of the necessary polysaccharides.

Though Srinivasan continues testing other concentrations, her present targeting of microplastics calls for one gram of her polysaccharide combination per liter of water. Given that big cities each treat hundreds of billions of liters annually, widespread adoption of her solution could spark a vast new market for okra and tamarind. This could be similar to the way corn production shot up dramatically as the market for ethanol expanded, said Rodolfo Nayga, head of Texas A&M’s Department of Agricultural Economics.

We’re still a ways from economists predicting an okra boom, but it’s conceivable. Such an outcome would have been hard to imagine—for Srinivasan, let alone anyone else—all those years ago, when she was happily devouring her mother’s bhindi masala.

This story appeared in the July 2022 issue of Texas Monthly with the headline “A New Use for Okra.” An abbreviated version originally published online on April 21, 2022, and has since been updated. Subscribe today.

- More About:

- Health

- Water

- Stephenville