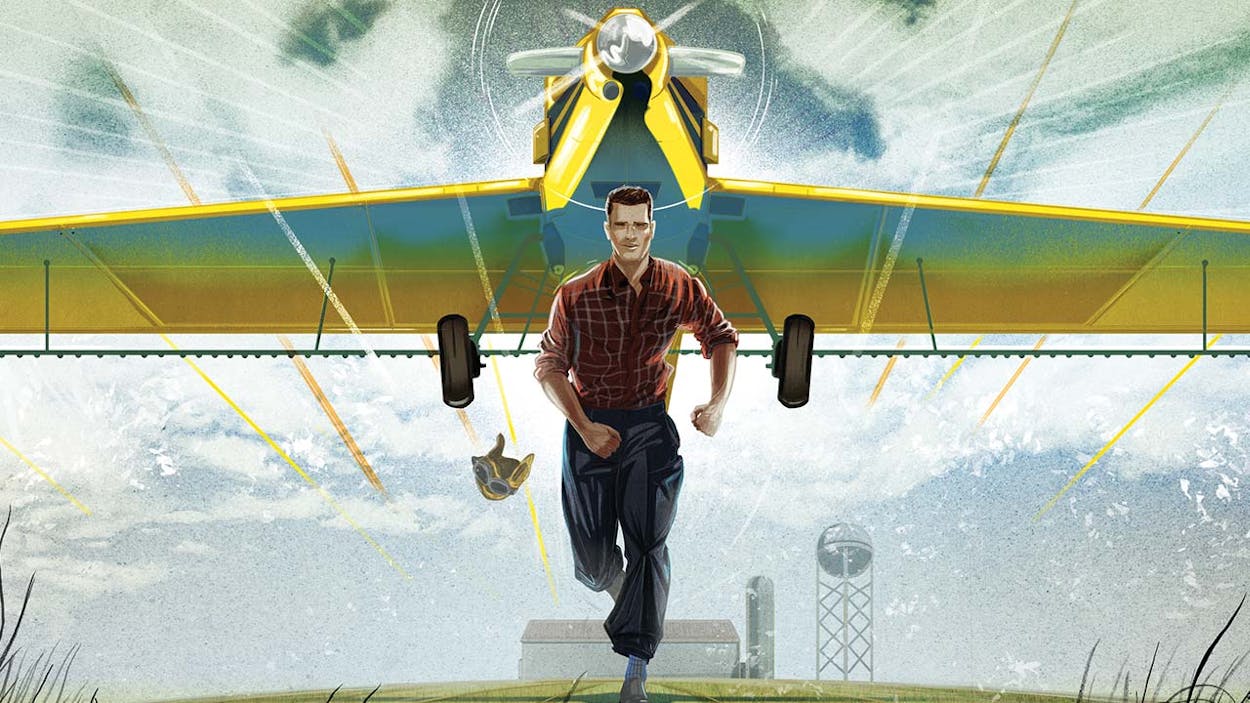

On a January day in 1958, a group of local businessmen gathered at an airfield on the outskirts of Olney to get a firsthand look at a piece of machinery they’d hoped would be the town’s economic savior. What they saw was a lopsided propeller plane—one landing-gear wheel was bigger than the other—piloted by a rail-thin young man in a ragged jacket. One of the businessmen turned to another and asked, “What have we done?”

The pilot standing before them was Leland Snow, a 28-year-old native of the Rio Grande Valley, who was already well on his way to becoming the Thomas Edison of agricultural aviation. The crop duster Snow had arrived in was one of his own invention; he’d designed it himself before he’d finished college and completed it soon after graduation. The aircraft’s lopsided appearance was the result of a last-minute repair for which he’d used the only spare wheel he could find.

Snow’s plane was a vast improvement over the crop dusters that were used throughout the world, but no one in his native Brownsville or nearby Harlingen, where he went to high school, would lend him enough money to build them in quantity. So he began looking elsewhere for a place to set up a factory. In Olney, about 45 miles south of Wichita Falls, the oil fields were playing out, the railroad had bypassed the town, and city leaders were looking for an economic boost. They leveraged the one asset they had left—an airfield built for the Navy during World War II to train bomber pilots—and pooled their lines of credit, about $100,000 in all, to fund Snow’s aircraft plant.

The investment paid off. Today Snow’s company, Air Tractor, generates about $108 million in annual sales, employs 250 people, and makes up 85 to 90 percent of the domestic market for agricultural aviation.

Crop dusting is a niche in commercial aviation—there are only about three thousand agricultural airplanes in service—one that requires a high degree of skill because the planes must make precise turns close to the ground and the spraying itself demands a great deal of maneuverability. About 71 million acres of cropland a year in the United States are treated with aerial spraying, and most of that work is done with Air Tractors. It’s not a stretch to say that if you’ve eaten a vegetable or piece of fruit or worn a cotton shirt, you’ve probably benefited from Snow’s innovations. “Thanks to Leland Snow, we’re flying much more efficient, much safer, much more reliable, and much more powerful aircraft,” says Andrew Moore, the executive director of the National Agricultural Aviation Association.

In all, Snow is responsible for nearly thirty aircraft designs, a legacy that sprang from a childhood fascination with flight. By age six, he was determined to be a pilot, and three years later he was building balsa-wood-and-tissue-paper models with wingspans longer than he was tall. At fifteen, he started working at the Harlingen airport in exchange for flying lessons, and he made his first solo flight two years later, getting his pilot’s license, so the story goes, before he learned to drive a car. After graduating from high school, he paid $200 for the wreckage of an Aeronca plane that had been torn apart in high winds and restored it himself. He put it back together in time to fly it to Texas A&M, where he studied aeronautical engineering.

The summer before his senior year, Snow got a job flying crop dusters in the Valley, and he quickly figured out that the planes used to spread pesticides were ill-suited for the task. Many were surplus World War II aircraft that had hoppers and spraying mechanisms added. “He realized while he was still at A&M that there was a commercial opportunity to build a purpose-built airplane,” says Jim Hirsch, Air Tractor’s president. Snow envisioned a plane with wings attached to the base of the fuselage, which would increase the dihedral, or upward angling of the wings, giving the plane a great deal of stability despite its heavy load.

Using his mother’s car as collateral, Snow borrowed $1,200 from a bank in Harlingen, and two years later, in 1953, he finished what became the Snow S-1, the first airplane designed specifically for spraying crops. Rather than selling the wood-and-canvas design, Snow started his own crop-dusting business, spraying fields in the Valley. The next year, after working all summer, he extended his flying season by taking the plane to Nicaragua, where the spraying ran from October to December. Several pilots there were so impressed with his plane that they wanted to buy one. He returned to Texas and began designing a metal version, later dubbed the S-2, which he completed in 1956.

Before he could sell his planes, though, Snow needed certification from the Civil Aeronautics Administration. So he became his own test pilot. In late 1957 he took off on the final test, demonstrating the wings’ structural integrity as a federal inspector watched from the ground. He put the plane in a steep dive, then pulled back hard on the control stick. As the plane came out of its dive, its left wing snapped off and the aircraft began spinning violently. Although he almost blacked out, Snow managed to parachute to safety. Afterward, rechecking his design calculations, he found the cause: a single misplaced decimal point. “From that experience I learned to check my work,” Snow said later. “I did all the calculations by slide rule back then. If you move it one way, you add a decimal place, and the other way you take away the decimal. I had under-designed a key fitting on the wing by a factor of ten.”

Snow soon had more than forty orders for the S-2 (which, with the decimal point in the right place, received government certification), and he knew he needed more money than he could borrow against his mother’s car. He found his investors in Olney, where, in its second year, the Snow Aeronautical Company would build thirty S-2s. Production rose steadily, and a prominent ag-aviation magazine dubbed the plane “the answer to a duster’s prayer.” But a customer’s lawsuit over a crash (unrelated to the wing design) compelled Snow to take on two partners to keep the company afloat. A few years later, in 1965, the new investors forced a sale to Rockwell-Standard, the company that, as Rockwell International, would later build the original space shuttle orbiter for NASA.

Rockwell made Snow a vice president and left him in charge of the plant, but he missed running his own company. “He had to answer to this corporate headquarters,” Snow’s daughter, Kristin Edwards, says, “and that just wasn’t his thing.” Five years after the sale, Rockwell closed the Olney plant and moved production to Albany, Georgia. But Snow refused to abandon the town that had given him his start. He resigned from Rockwell and immediately began drawing up plans for a new plane. By 1972, he was ready to launch a new company, Air Tractor, with some of his own money along with a small business loan. Air Tractor delivered its first aircraft two years later, and soon after, it built a new plant near the original Snow Aeronautical facility in Olney.

Over the next few decades, Air Tractor’s yellow planes came to dominate the crop-dusting market. Even today, the only competitor of consequence is Thrush Aircraft, which bought the old Rockwell operation in 2003 and makes planes based on Snow’s S-2. “That’s our primary competitor—we’re competing with the original design,” says Hirsch.

Snow was still running the company when he died four years ago, at age eighty, while jogging near his home, in Wichita Falls. But a few years earlier he did something unusual. He had always been haunted by Rockwell’s abandonment of Olney, a town he had come to love, and he swore he would never let that happen with Air Tractor. And so, in 2008, he sold the company to his employees. “It was a way for him to ensure that Air Tractor wouldn’t be bought up by some mega-conglomerate that would move it off somewhere,” says Edwards, who’s an Air Tractor vice president. Only about seven thousand companies in the U.S. are owned by their employees, out of millions of businesses nationwide. For Air Tractor, turning employees into owners helped boost production to as many as 180 aircraft a year in 2012 and 2013, when demand was at its peak, and has helped keep turnover low.

Although it’s an aviation company, Air Tractor’s fortunes are closely connected to agriculture markets, which account for more than 85 percent of its sales (firefighting and military use make up the rest). The decline in commodities prices over the past year—globally, food costs are lower than they’ve been since 2010—has hurt business; this year, output is down to 120 planes. That sort of unpredictability is one reason the company has, in recent years, focused on expanding its reach into international markets. “Half of everything we sell is exported,” Hirsch says. “That’s our real opportunity for continued growth.”

For small companies, though, exports can be tricky. The banks in developing countries often can’t take on the risk of making large loans, and American banks are less willing to lend to foreign buyers because it’s more difficult to collect collateral in the event of default. The solution to this quandary has been the Export-Import Bank, a federal credit agency that guarantees loans to foreign customers of U.S. companies. Hirsch says roughly half of Air Tractor’s foreign sales are backed by Ex-Im.

So the company has been paying close attention to the current congressional battle over Ex-Im. This summer, Republicans, led by Senator Ted Cruz and Congressman Jeb Hensarling, of Dallas, blocked reauthorization of the bank’s charter. “The bank is a small-scale example of a larger and more dangerous threat: the shrinking of the free-market economy and the rise of a progressive welfare state—with its attendant cronyism, public-private partnerships, and spreading government economic controls,” Hensarling wrote in a letter to his fellow Republicans published in the Wall Street Journal. Ninety percent of the bank’s transactions support small- and medium-sized businesses like Air Tractor, but critics point out that big companies like Boeing, Caterpillar, and General Electric sop up billions in loan guarantees and don’t need the subsidies. Ex-Im advocates note that the agency has a default rate of less than 2 percent, lower than most commercial banks, and it supports itself with fees collected from borrowers and doesn’t rely on taxpayers.

For Hirsch, the ideological arguments ignore practical reality. Without the bank’s guarantees, many of Air Tractor’s customers can’t get financing to buy its planes. Texas companies are the country’s biggest beneficiaries of the bank’s loan guarantees and insurance, making it ironic, as Hirsch notes, that the Texas delegation is at the forefront of the opposition. But the battle hits even closer to home for him. “I went to high school with Jeb Hensarling, in College Station, and for him to be leading that opposition . . . ,” he says, shaking his head as his voice trails off. They weren’t close friends, but Hirsch’s mother taught Hensarling (and, several years later, me) algebra.

In October, House lawmakers used a procedural move to force a vote on reauthorizing the bank, which passed by a lopsided 313–118 vote. Hirsch is hopeful that the Senate will approve the reauthorization when the bill comes before it in December. In the meantime, Air Tractor is looking for alternatives. The company itself has guaranteed loans to a handful of customers, but it can’t sustain that risk for long. Other options are more expensive and less readily available, so future overseas sales have been in limbo.

The conventional wisdom is that the bill will pass in the Senate, despite the apparent opposition of majority leader Mitch McConnell. But if it doesn’t, a company that has flown so high for decades might be grounded by politics.