Once a week, Sunny Moberg sets a cutting torch onto the surface of steel containers that once held one thousand gallons of flammable fuel. These propane tanks, delivered to Moberg’s shop in Dripping Springs by the trailer load, are all salvaged. Some were decommissioned decades ago. It seems counterintuitive to introduce fire to such a container, but Moberg is used to it. “I’ve been cutting into tanks for twenty years,” he tells me. I ask him whether he worries about an explosion from unreleased propane, a gas that’s heavier than air, sitting in the tanks after all these years. “I don’t want to say I get too comfortable,” Moberg says, adding, “I say a little prayer before cutting into each one.”

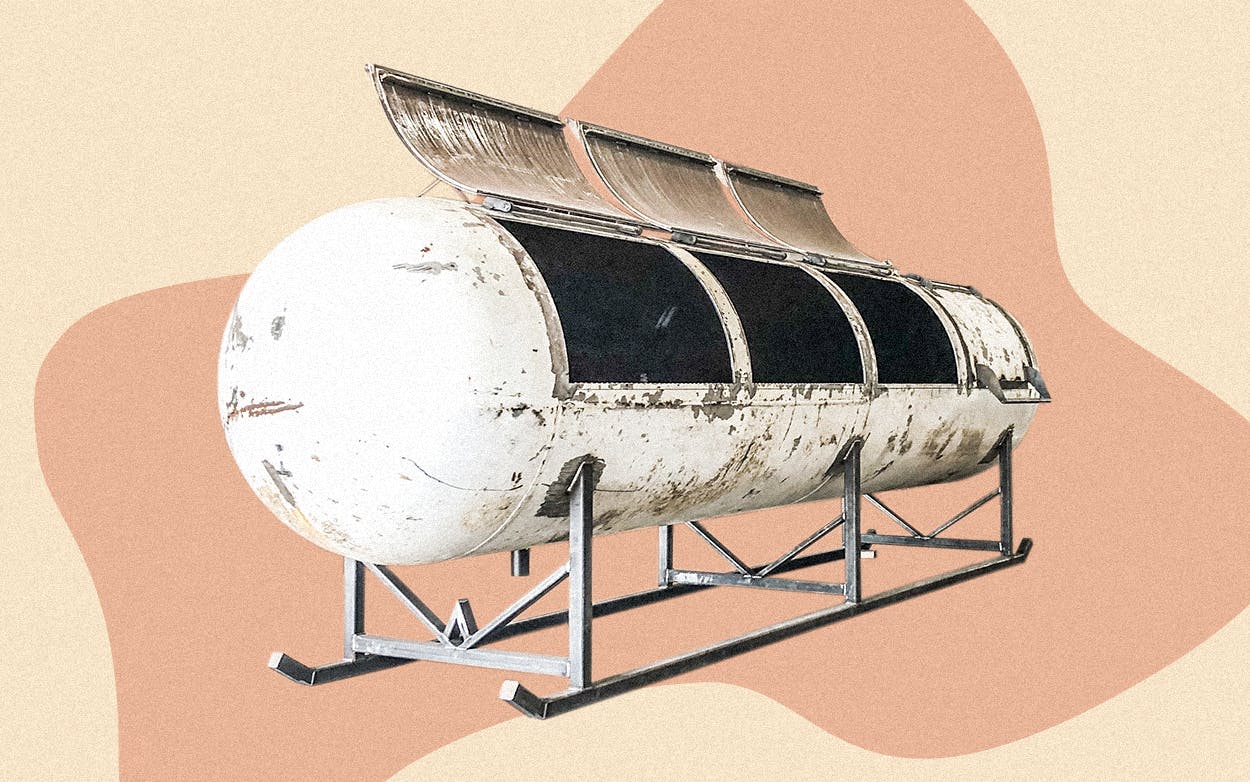

What was once considered trash is now in high demand. The popularity of smokers made from propane tanks has risen right along with the Texas-style barbecue boom across the state and the world. Instead of discussing smoker size by length, width, or cubic inches, it’s gallons that have become the most recognizable unit. One-thousand-gallon smokers are the big ones inside many restaurant smokehouses. They also come in five-hundred and 250-hundred-gallon sizes, but the latter are often cut in half to serve as fireboxes for the big boys. All of them are getting harder to find.

Moberg, who owns Moberg Smokers, says he used to find them for free, but salvage yards have gotten wise to the popularity of propane tanks. The 16-foot-long tubes, with half spheres on either end, have become the badge proving a new barbecue joint’s wood-cooking bonafides. Beauty shots of one-thousand-gallon smokers in barbecue joints all over the world—Moberg has smokers headed to Australia, New Zealand, and Canada currently—have become almost as popular as photos of the barbecue itself. Moberg is now paying anywhere from $300 to $1,200 for a one-thousand-gallon propane tank. He even jokes, “There may be a day where I’ll have to buy from the manufacturer,” but quickly adds that the older ones are prized because the walls of the tanks are thicker, making for more efficient smokers. They’re a finite commodity.

As the grandson of Albert C. “Smokey” Denmark, the founder of Smokey Denmark’s Smoked Meats Co., Moberg says, “I have smoking in my genes.” The first smoker he ever built was for himself, made from a water heater, and he describes it as “a horrible smoker.” He built another from a propane tank in 1992 after a customer brought it to him. It was an improvement, but he didn’t think much about making a career out of it then. Moberg’s welding skills were focused on building trailers. It took a Texas pitmaster to first make these smokers a real commercial venture.

In 2015, John Lewis Jr. was working as the pitmaster at la Barbecue in Austin, but was planning a new barbecue joint in Charleston, South Carolina. He needed some additional funding for what would become Lewis Barbecue in 2016. With the help of his father, John Lewis Sr., Austin Smoke Works was born in a welding shop. Their first customer was the mayor of Brownsville. Then Cattleack Barbecue in Dallas ordered one, and a few went to ZZQ in Richmond, Virginia. Each new order that came in was bittersweet for Lewis Jr. He had designed these smokers, and “I didn’t want anyone to get the design,” he says, noting that some details had been proprietary. Still, he needed the money. “I had to do it,” he says.

Those design details may seem trivial, but they can mean the difference between a consistent cooking temperature versus unforgiving hot and cold spots inside the smoker. This style of smoker isn’t mechanical. There are no blowers, fans, or automatic dampers. There’s no rotisserie. It’s just wood fire and fluid dynamics. Briskets sit idly within that 16-foot-long cooking chamber, and hopefully, a continuous ribbon of sweet smelling smoke wafts along their surface between the firebox and the exhaust stack at the other end. It requires draw, or a pressure difference that pulls heat and smoke from the firebox and slings it up the exhaust stack. Ideally, that moving air drops as little of its heat as possible from one end of the cooking chamber to the other. It’s the same concept as the old brick pits at joints like Kreuz and Smitty’s in Lockhart, just done with a new material on smokers that are a bit more portable.

Despite the overwhelming popularity of the one-thousand-gallon size, Lewis believes a five-hundred-gallon smoker size is naturally suited to the task of keeping an even airflow and temperature differential. “A lot of tricky things go into it to try and mimic what happens in a five-hundred-gallon pit into a thousand-gallon pit,” he says, but concedes, “If you’re going to make one fire, you might as well be cooking more things, right?” That’s why he uses a fleet of four one-thousand-gallon smokers from Austin Smoke Works in his Charleston pit room.

Lewis, who first cooked on a one-thousand-gallon smoker at Franklin Barbecue, said he studied that pressure imbalance to try and improve the draw when he built his first smoker. When he took over pit duties at la Barbecue in 2012, he wasn’t happy with the smoker he inherited. So, years before Austin Smoke Works was founded, he built his first pit using a propane tank as a replacement. “I fired it up for the first night” once the new smoker was competed, he says. Lewis continues the story with pride still in his voice: “I was sitting in a lawn chair about ten feet away for the firebox door, and had lit a fire in there. I sat down, opened a beer, and lit a cigarette. It started drawing my cigarette smoke, from ten feet away, into the firebox and through the smoker.” That’s when he knew his smoker design was a winner.

Aaron Franklin doesn’t offer his big smokers for sale, but he’ll teach you how to build one on TV. In Episode 4 of BBQ with Franklin, from 2015, he walked through the process of turning a 250-gallon propane tank into a smoker. Franklin was something of a pioneer when it came to popularizing this style of smoker. “I definitely didn’t start it,” he says modestly, but admits, “I may have a had a small role in making it more widely known, perhaps.” It began with “Muchacho” in 2011. Franklin needed additional barbecue capacity for the brick-and-mortar he was renovating at the time, so he welded together his first one-thousand-gallon smoker. He’s built plenty more since then, each with its own tweaks on the original, but even after surviving last year’s pit room fire, “[Muchacho] is still chugging along,” Franklin says, adding, “It’s still kind of our favorite one.”

These days, the Franklin pit room has five thousand gallons of brisket capacity. The five smokers are regular backdrops for pit room photos. Any pitmaster wanting to emulate Franklin and having the means to buy a new smoker will likely choose a similar model. The smoker alone has become a symbol of Texas-style barbecue around the world in just a few short years. Many of Franklin’s were built at his welding shop in Bastrop with the help of brothers Matt and Caleb Johnson. They left from underneath the Franklin Barbecue umbrella in early July and struck out on their own. There’s now a few dozen raw propane tanks littering the lot outside their shop, Mill Scale Metalworks, just north of Lockhart.

“We had such a great run at Franklin,” Matt Johnson tells me during a meal at Kreuz Market, “and one of the great things was that there was guaranteed work.” Now they have to get the work on their own, but it hasn’t been a problem. The only marketing they’ve done thus far is making shirts and hats, and posting photos on an Instagram account. Already they’re building one-thousand-gallon smokers for customers in New York, Houston, and Berlin. Matt says, “It’s crazy to hear someone with a German accent talk about wanting a dirty, old, ugly, unpainted pit made out of a propane tank.”

Matt was happy to talk details of the design process. “The height of the firebox determines how even your top and bottom heat are,” he said. The goal for them is to design pits with even convection and even heat on the top and bottom of the meat. “One thing we’re trying to avoid is having to rotate meat,” Matt says. They do this in part by insulating the firebox so that it burns fuel more efficiently. The firebox is made up of two tubes, one larger than the other, with an air gap between them. A ceramic fiber blanket fills the air gap to provide the insulation. It’s an additional layer that Franklin finds unnecessary, and even detrimental to the barbecue. “The problem with an insulated firebox, especially in Texas, is that once it gets hot, it’s hot,” Franklin says. “It’s basically an oven.” He means that if the coals stay hot for a long time, there’s no new wood and therefore no new smoke introduced to the barbecue.

Franklin is a purist in this, and is overruled by most other pit fabricators. Moberg says his insulated firebox helps keep an even temperature. “Once you get that thing chugging,” he says, “it’s about eight degrees off from one end to the other.” It also reduces wood consumption by up to forty percent. It’s a big selling point to customers, but I guess that agrees with Franklin’s assessment. Franklin also won’t add shelves into his smokers for additional capacity, which should be pretty tempting for a guy who can smoke a finite amount of brisket every day. “When you put all those shelves in there,” he says, “there’s so much evaporative cooling when you load it down, you can’t expel that moisture quick enough to get a good bark to form.” Again, most pit makers now offer the option of shelving, and even rods inside the smoker from which sausages can hang.

Dennis Roach was proud to show me the options on a five-hundred-gallon smoker he was building in his driveway. The welder has set up shop at his home in Saginaw, just north of Fort Worth. He saw the demand for this style of smoker and quit his job as an industrial welder to start his own company, El Cucaracho Smokers. Business is brisk. He and his father were putting the finishing touches on a trailer-mounted smoker headed to Austin. He just sent one to Canada and is working on a one-thousand-gallon smoker for the upstart Zavala’s Barbecue in Grand Prairie. “I know I’m gonna outgrow this,” he says while standing in his garage, which no longer has room for vehicles. He has smoker orders to last him until April right now. All the customers have come through Instagram thus far.

Roach fell in love with barbecue during a 2015 road trip to Austin. He loved the brisket from Franklin Barbecue, and used Franklin’s design as an inspiration to build his own 250-gallon smoker. “It cooked good,” he said, so he sold it and built a five-hundred-gallon smoker. He has since sold that one, too. “I’m embarrassed to say, but I’ve been cooking on a Traeger,” Roach says sheepishly, referring to the popular brand of pellet smokers. “I don’t even have a pit of my own,” he said, laughing. “I can’t keep one.”

Just like with Texas barbecue, these smokers take time and attention to build, and folks often wait in line for them. Roach and his father spent a month building his latest trailer-mounted smoker. It’s a lot of work, yet Roach is only charging $9,500 for a one-thousand-gallon smoker on skids. On the other end of the spectrum is Austin Smoke Works, which charges $21,000 for that size. Lewis Jr. defends their high cost saying, “Cutting through metal, even if you’re using a plasma cutter and all the things we have in this day and age, it’s still a lot of man hours.” He estimates that it requires four-hundred man hours for a single one-thousand-gallon smoker fabrication. It takes the Mill Scale brothers about three weeks to build one on skids at their shop. They charge $16,000, but can’t predict how high that might go up because of President Trump’s new trade war. Of late, tariffs have added 35 percent to their total steel cost.

Sunny Moberg has an even harder time with pricing. His popularity has exploded, even spawning the hashtag #GottaGettaMoberg. The volatile steel pricing means he has to hope the $13,000 he charges now will cover his costs when he builds that smoker slated for April of 2020. That’s how far out his orders go, even though he and his brother-in-law, Guy Hailey, can churn a new one out every week. He says his steel supplier can now only guarantee pricing for 24 hours. His steel metal and tubing costs are up 75 percent. There is one discount available to customers, however. Moberg’s smokers are known for a slick paint job that looks closer to a factory automobile finish. He’ll knock off $500 if you opt for the raw steel look.

Moberg also has some safety advice for welders who plan to jump into the propane smoker business. “If it smells like stale air, like from inside a bike tire, then it’s probably pretty safe.” But he recommends the long accepted method of making sure the tank is safe before putting a torch to it. “If a weekend warrior is going to do this, fill it full of water, put the soap in if you want, and let it sit a couple days,” he says. It should be fine after that, but even then you might catch a whiff of what you think is propane. It’s really mercaptan, the stuff added to otherwise unscented propane and natural gas so it can be easily identified. The steel, in its pores, “holds onto the mercaptan smell,” Moberg says. He offers this advice because there’s currently plenty of business to go around when it comes to building Texas-style smokers. He says, “As long as this Central Texas craft barbecue craze is still on fire, I’m in good shape.”

There’s a cartoon that Moberg remembers from his childhood. He describes it, saying, “There was a bully dog, and he kept on asking for gravy. ‘Don’t forget the gravy. Don’t forget the gravy.’ At the end of the cartoon, they had him strapped down to a table with a funnel in his mouth. They’re pouring gravy down this dog’s mouth, and saying, ‘We didn’t forget the gravy.’” Moberg laughs at the cartoon’s new significance in his life.“I’m blessed, and I’m happy for all this,” he says, “but the gravy is pouring down my throat.”

Moberg is a bit embarrassed talking about his newfound popularity in the business, and wishes he could build smokers faster. He gets eighty messages a day inquiring about smokers, all of them electronic. He doesn’t publish his phone number or address. “I don’t see forty percent of my customers,” he says. Some he never even talks to on the phone, but there is one meeting that was particularly memorable, in April 2017. He and Michael Wyont of Flores Barbecue in Whitney, sat outside his shop after loading Wyont’s new smoker on his trailer. “Is this the calm before the storm?” Wyont asked, speaking for the both of them. Moberg’s name was just getting traction in the barbecue business, and a few months earlier, Flores Barbecue has just gotten a glowing review on this site. The next month, Texas Monthly released the 2017 Top 50 BBQ list. Flores Barbecue was on there, and eight of the barbecue joints on the list were using a Moberg smoker. This year, Wyont just had his second Moberg delivered in July. Wyont recalls: “As soon as I picked up the first one, I said, ‘You might as well put me down for a second one.'” Good thing he got in line early.

- More About:

- Franklin Barbecue